On the Job Practices: Sling Harness Safety and OSHA Requirements

When your crew needs to move a bulky or heavy item as part of their daily work, sling harnesses can be a great benefit, allowing them to quickly move that part or equipment into place without the risks of heavy lifting. But wherever heavy items are being moved mechanically, there's always a chance of danger and possible injury to members of your crew. Here are some basics on sling harness safety and how OSHA and ASTM standards come into play on the job.

Basic Sling Harness Safety

When working with sling harnesses, there are some common-sense safety precautions to take. Check that the load is within the capacity of the sling harness and the attachments you're using to prevent injury if the harness breaks while carrying too heavy a load. Inspect the harness regularly, which can be annually for a harness in regular use, quarterly to monthly for one receiving heavy use and as recommended by a qualified individual when it's used infrequently or for special circumstances. Check for wear, excessive pitting or corrosion, defective welds, cracks, nicks, breaks, stretching, bends, excessive throat opening in hooks, discoloration from excess heat, illegible or missing identification and any other signs that the harness may have been stressed and damaged during use.

If any of the above issues arise, properly repair the sling before putting it back into service. When on the job, ensure no member of your crew places a body part between the sling and the part being lifted or between the harness and the lifting device. Don't allow your crew to ride the sling harness unless it's specifically designed for that purpose, and ensure that nobody is in the line of motion or beneath a loaded harness when work is ongoing.

OSHA Requirements and ASTM Standards

OSHA requirements for the safe use of a sling harness include the above practices, but also require that the load be secured in a safe fashion to prevent injuries. When it comes to the lifting capacity of the sling harness, ASTM standards fall into play, specifically A906-02, which involves the testing of Grade 80 and Grade 100 alloy steel chain slings. By ensuring that your sling harness meets this standard, you can ensure that your crew will remain safe on the job.

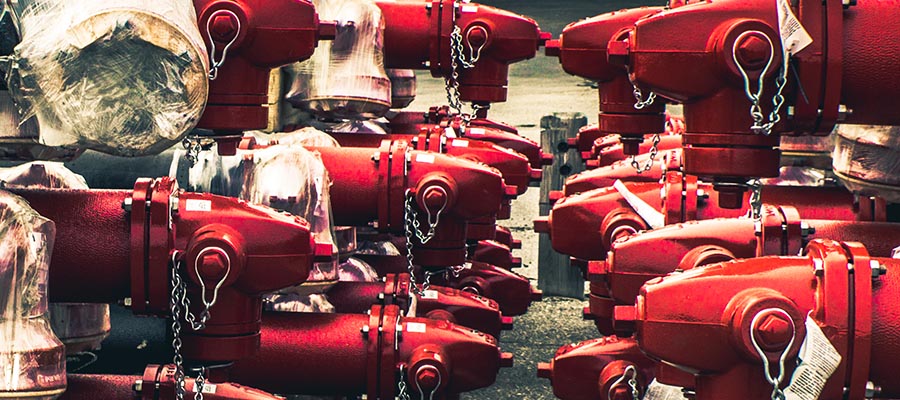

Sling harnesses are a great tool to use when heavy lifting is involved, but proper maintenance, regular inspection and safety procedures are necessary to keep your crew working safely. If you have a sling harness that is below safe limits, it's time to replace it. When it comes to moving waterworks materials, it's even more important to use the right tool for the job. Our lifting tools, including our Hydrant Setter, Valve Setter and Catch Basin Sling, are constructed from components that exceed OSHA and ASTM standards to provide your crew with the safest, most effective slings for the job. At New Concept Tools, we understand your need for safe equipment and effective tools that are intended for use in the waterworks industry. Please feel free to contact us today with any questions or for more information on our line of quality tools built for the demanding work waterworks employees see every day.