How to Use a Hydrant Setter for Improved Safety and Performance

Hydrants can be a significant part of your water utility's overall assets. They're also heavy, bulky and difficult to place correctly without a lot of trouble. Because they can involve trench work, it can be dangerous for your crew to install, with potential for serious injury if something goes wrong. For that reason, the experts at New Concept Tools have developed a hydrant setter that helps protect your crew and your hydrants from damage. Here's a quick look at how to use a hydrant setter to improve safety and speed up the installation of this difficult but necessary part of your water utility system.

To put the hydrant setter into use, you'll need to first remove the nozzle caps on the sides of the hydrant, something which our adjustable hydrant wrench can be incredibly helpful for. You'll then slide the lifting rings into place, which are perfectly sized for the hose nozzles, preventing damage to the threads during the lifting process. After the lifting rings are fully seated on the nozzles, you'll replace the nozzle caps, keeping the lifting rings with the chains pointing up towards the top of the hydrant to hold them in perfect position on the nozzles once the caps are fully tightened down.

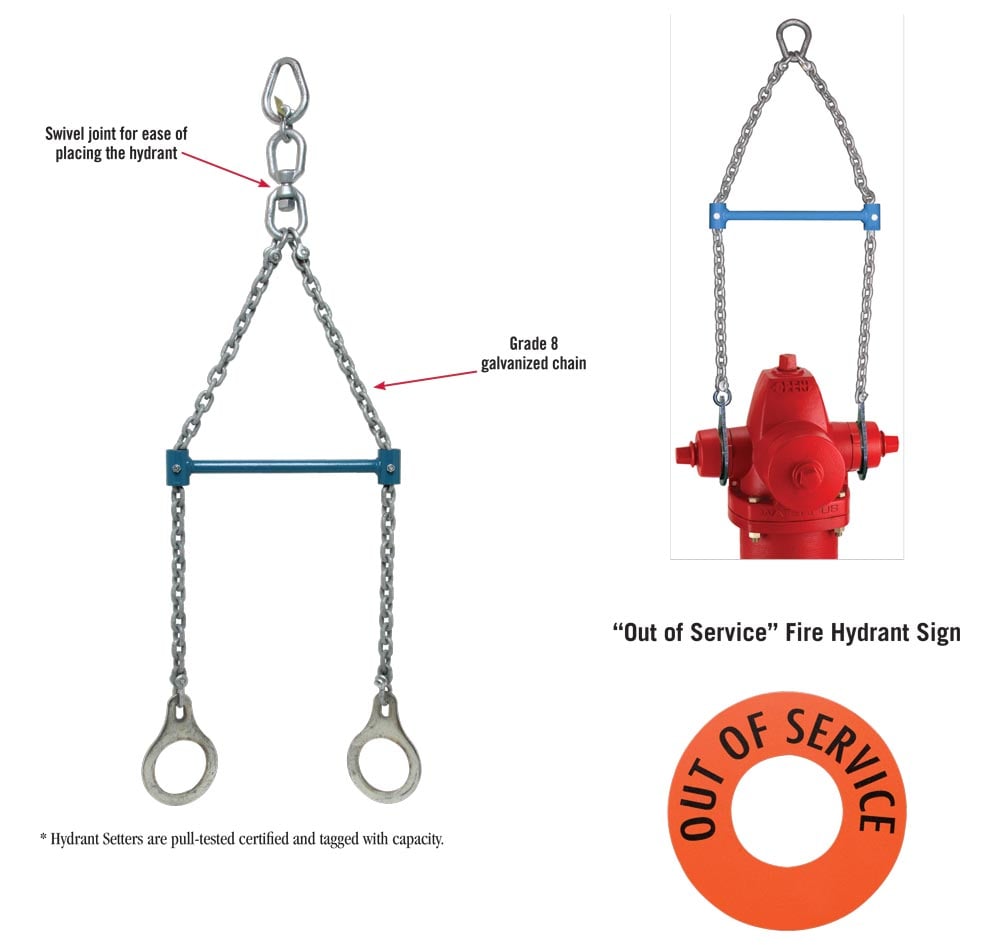

The spreader bar keeps the lifting rings at the proper position and prevents damage from the chains and hydrant swinging together during the lifting and setting process. The chain is connected to the lifting ring using a swivel joint, which makes it virtually effortless to rotate the hydrant into the correct position for installation without the need for a lot of repositioning of heavy equipment around the installation on site.

The hydrant setter features a grade 8 galvanized chain for superior strength and durability in wet conditions. The lifting ring and spreader bar are finished to reduce corrosion. The lifting ring is large enough to easily attach to a number of different types of heavy machinery with very little effort. This, in turn, allows your team to quickly move the hydrant in and out of position, whether you're installing a new hydrant or pulling an old one for repairs or maintenance.

With hydrants weighing up to half a ton, the hydrant setter is an important part of getting the job done without injuries to your crew or damage to the hydrant itself due to an accidental drop or failure in an improvised sling used as a setting tool. Imaging the ease of being able to simply remove the nozzle caps, put the lifting rings in place, putting the nozzle caps back on, hooking up to a backhoe or forklift and then simply spinning the hydrant into the right position for installation.

By using a hydrant setter to place and install your hydrants, it's much easier to reduce the risk of injury to your crew or damage to the hydrant itself. But unlike other tools, such as slings that are improvised for use in setting hydrants, our hydrant setter is designed to prevent slippage with the presence of a spreader bar and lifting rings that are the perfect size for hose nozzles, because it has been specifically designed for use with hydrants. If you're ready to see the difference that job-designed tools can make for your water utility, please feel free to contact the experienced professionals at New Concept Tools today for more information.