How to Safely Install a Hydrant

When you're working with heavy items on a daily basis, the risk of injury is a very real danger that can take you, your employees or your team out of the action for a significant amount of time. Hydrants are often one of the heaviest items installed by waterworks professionals. They weigh as much as 1,000 pounds, making them ungainly to move and dangerous if they're not handled properly. In this article we'll discuss how to handle and how to install a hydrant safely, to ensure that you and your team can perform a hydrant installation quicker without risk of injury.

Adjustable Hydrant Wrench and Hydrant Setter Product Video

Because of a hydrant's significant weight, some municipalities have gone to using teams of maintenance workers to set them into place. The problem with this approach is that if one person in the wrong position or loses their grip, the entire lifting team can be injured, with strained muscles, smashed feet and pinched fingers being quite common or worse. The hydrant itself is also in danger of being damaged.

Installing a Hydrant

Many municipalities have gone to using mechanical assistance in the form of a lift or crane, but if the attachment point is not secured properly, the hydrant can slip out of the harness, potentially causing injury to the installer and to the new hydrant itself as it falls. Some lifting tools available on the market will provide a secure hold, but take significant amounts of time to install and remove, slowing down your team's production rate and tying them up from other tasks they need to get done. Our solution for hydrant installation is a Hydrant Setter.

Installing a Hydrant With a Hydrant Setter

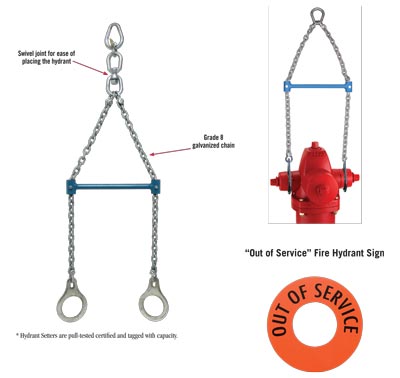

At New Concept Tools, we've developed a great hydrant setter to help simplify the process of hydrant installation. It also helps minimize the dangers and expenses of lifting and installing such a heavy object. Our hydrant setter has a pair of lifting rings which are held in place with the hose nozzle clamps, ensuring it won't fall and cause injury to your team or your hydrant. The lifting rings are held in perfect alignment through the use of a spreader bar, fit over 2-1/2" hose nozzles.

By designing the hydrant setter rings to the uniform 2-1/2" nozzle size, our hydrant lifter will work with virtually any hydrant on the market that uses this standard nozzle size, allowing you to use it for a wide range of hydrant designs in your system. Unlike some hydrant setters and lifts that will only work with hydrants that have a significant bonnet. Because it safely secures and lifts the hydrant with mechanical assistance, our hydrant setter allows the hydrant to be installed with only two employees, one that is running the lift or backhoe and the other controlling the movement of the hydrant into position. The all-metal construction means you won't have to deal with the dangers of webbing slings that can slip and fray. The top of the hydrant setter incorporates a swivel link to insure smooth rotation of the hydrant during installation.

In the waterworks industry, you don't need tools that will make do, you need tools that are made for you. At New Concept Tools, we've been developing tools specifically for the utility and waterworks sector since 1978, extensively field-testing each new design until we can be sure it exceeds our customer's every expectation. If you're in need of a Hydrant Setter be sure to click the button below to view available options.